I’m in the process of replacing a old radiator system with a centrally-ducted, air-source heat pump system with electric resistive backup heat. I’ve found that the default ecobee algorithm seems to behave surprisingly poorly for this system, and wanted to write up some of the settings that I’ve found yield better behavior.

A disclaimer. I’m not an HVAC professional. I have two decades in software operations, a background in physics, and far too much experience inferring system dynamics from timeseries graphs. This advice may void your warranty, burn your house down, etc.; everything you do is at your own risk.

The System

First, a bit about the system in question. You can skip this section if you know about heat pumps, short cycling, staging, etc.

There are two main subsystems: a heat pump and an air handler. The heat pump sits outside: it has a fan which moves outside air over a heat exchanger, and a compressor, which compresses a working fluid. The working fluid is connected in a loop to the air handler, where it runs through another heat exchanger to heat or cool the inside air. The air handler also has a blower fan which circulates air through the whole house. If the heat pump can’t keep up with demand, the air handler also has a pair of resistive electric heating coils, called aux heat, which can supplement or take over from the heat pumps.

A few important things to know about heat pumps. First, electric resistive heaters have a Coefficient of Performance (CoP) of essentially 1: they take 1 joule of electricity and turn it into 1 joule of heat in the air. My heat pumps have a typical heating CoP of about 2-4, depending on temperature and load. They take 1 joule of electricity and suck 2 to 4 joules of heat from the outside air into the inside. This means they cost 2-4 times less (in electric opex, at least) than a standard resistive electric heating system.

Second, heat pumps, like A/C systems, shouldn’t start and stop too frequently. Starting up causes large transient electrical and mechanical stresses. Ideally they should run at a low speed for several hours, rather than running at full blast, shutting off, then turning on again ten minutes later. This is called “short cycling”.

Third, the heat pump’s fan, heat pump’s compressor, and the air handler’s fan are all variable-speed: they can run very slow (quiet, efficient), very fast (loud, more powerful), or at any speed in between. This helps reduce short-cycling, as well as improving efficiency and reducing noise. However, directly setting compressor and fan speed requires a special “communicating” thermostat made by the same manufacturer, which speaks a proprietary wire protocol. My manufacturer’s communicating thermostats are very expensive and have a reputation for buggy hardware and software, so I opted to get an ecobee 3 lite. Like essentially every other thermostat on the planet, the ecobee uses ~8 wires with simple binary signals, like “please give me heat” and “please turn on the fan”. It can’t ask for a specific amount of heat.

However, all is not lost. The standard thermostat protocol has a notion of a “two-stage” system—if the Y1 wire is hot, it’s asking for “some heat”, and if Y2 is also hot, it’s asking for “more heat”. My variable-speed heat pump emulates a two-stage system using a hysteresis mechanism. In stage 1, the heat pump offers some nominal low degree of heat. When the thermostat calls for stage 2, it kicks up the air handler blower a notch, and after 20 minutes, it slowly ramps up the heat pump compressor as well. I assume there’s a ramp-down for going back to stage 1. They say this provides “true variable-capacity operation”. You can imagine that the most efficient steady state is where the thermostat toggles rapidly between Y1 and Y2, causing the system to hang out at exactly the right variable speeds for current conditions—but I assume ecobee has some kind of of frequency limiter to avoid damaging systems that actually have two separate stages with distinct startup/shutdown costs.

The air handler’s aux heat is also staged: if the W1 wire is hot, I think (based on staring at the wiring diagram and air handler itself) it just energizes one of two coils. If W2 is also hot, it energizes both. I think this is good: we want to use as much of the heat pump heat as possible, and if we can get away with juuuust a little aux heat, instead of going full blast, that’ll save energy.

In short: aux heat is 2-4x more expensive than heat pump heat; we want to use as little aux as possible. Short-cycling is bad: we want long cycle times. For maximum efficiency, we want both the heat pump and aux heat to be able to toggle between stage 1 and 2 depending on demand.

Automatic Problems

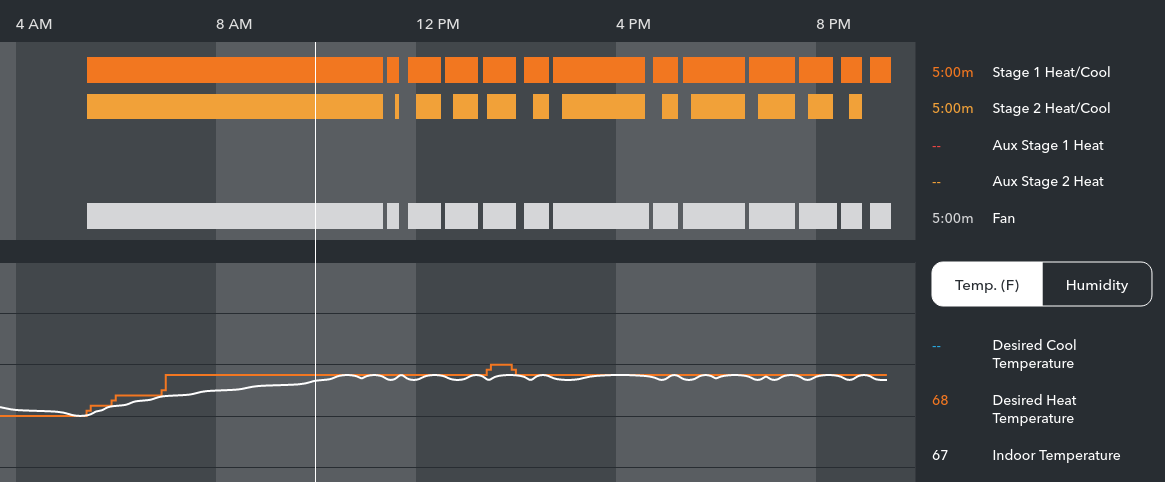

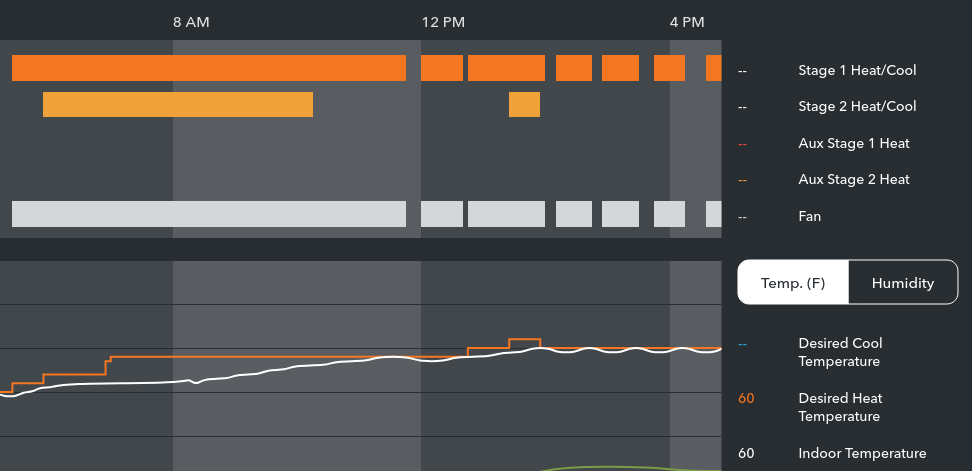

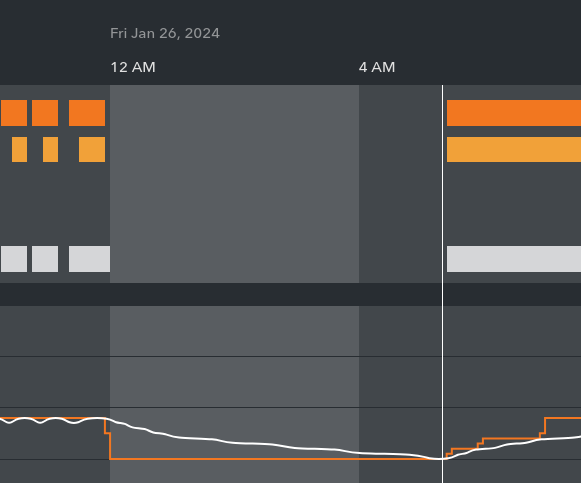

I initially left the ecobee at its automatic default settings for a few weeks; it’s supposed to learn the house dynamics and adapt. I noticed several problems. Presumably this behavior depends on weather, building thermal properties, HVAC dynamics, and however ecobee’s tuned their algorithm last week, so YMMV: check your system and see how it looks.

It’s kind of buried, but ecobee offers a really nice time-series visualization of thermostat behavior on their web site. There’s also a Home Assistant integration that pulls in data from their API. It’s a pain in the ass to set up (ecobee, there’s no need for this to be so user-hostile), but it does work.

Over the next few weeks I stared obsessively at time-series plots from both ecobee and Home Assistant, and mucked around with ecobee’s settings. Most of what I’ll describe below is configurable in the settings menu on the thermostat: look for “settings”, “installation settings”, “thresholds”.

Reducing Aux Heat

First, the automatics kicked on aux heat a lot. Even in situations where the heat pump would have been perfectly capable of getting up to temp, ecobee would burn aux heat to reach the target temperature (set point) faster.

Part of the problem was that ecobee ships (I assume for safety reasons) with ludicrously high cut-off thresholds for heat pumps. Mine had “compressor min outdoor temperature” of something like 35 degrees, so the heat pump wouldn’t run for most of the winter. The actual minimum temperature of my model is -4, cold-climate heat pumps run down to -20. I lowered mine to -5; the manual says there’s a physical thermostat interlock on the heat pump itself, and I trust that more than the ecobee weather feed anyway.

Second: ecobee seems to prioritize speed over progress: if it’s not getting to the set point fast enough, it’ll burn aux heat to get there sooner. I don’t want this: I’m perfectly happy putting on a jacket. After a bit I worked out that the heat pumps alone can cover the house load down to ~20 degrees or so, and raised “aux heat max outdoor temperature” to 25. If it’s any warmer than that, the system won’t use aux heat.

Reverse Staging

A second weird behavior: once the ecobee called for stage 2, either from the heat pump or aux, it would run in stage 2 until it hit the set point, then shut off the system entirely. Running aux stage 2 costs more energy. Running the heat pump in stage 2 shortens the cycle time: remember, the goal is a low, long running time.

The setting I used to fix this is called “reverse staging”. Ecobee’s documentation says:

Compressor Reverse Staging: Enables the second stage of the compressor near the temperature setpoint.

As far as I can tell this documentation is completely wrong. From watching the graphs, this setting seems to allow the staging state machine to move from stage 2 back to stage 1, rather than forcing it to run in stage 2 until shutting off entirely. It’ll go back up to stage 2 if it needs to, and back down again.

Manual Staging

I couldn’t seem to get ecobee’s automatic staging to drop back to stage 1 heat reliably, or avoid kicking on aux heat when stage 2 heat pump heat would have done fine. I eventually gave up and turned off automatic staging altogether. I went with the delta temperature settings. If the temperature delta between the set point and indoor air is more than 1 degree, it turns on heat pump stage 1. More than two degrees, stage 2. More than four degrees, aux 1. More than five degrees, aux 2. The goal here is to use only as much aux heat as absolutely necessary to supplement the heat pump. I also have aux heat configured to run concurrently with the heat pump: there’s a regime where the heat pump provides useful heat, but not quite enough, and my intuition is that some heat pump heat is cheaper than all aux.

I initially tried the default 0.5 degree delta before engaging the heat pump’s first stage. It turns out that for some temperature regimes this creates rapid cycling: that first-phase heat is enough to heat the house rapidly to the set point, and then there’s nothing to do but shut the system off. The house cools, and the system kicks on again, several times per hour. I raised the delta to 1 degree, which significantly extended the cycle time.

Large Setback with Preheating

A setback is when you lower your thermostat, e.g. while away from home or sleeping. There’s some folk wisdom that heat pumps should run at a constant temperature all the time, rather than have a large setback. As far as I can tell, this is because a properly-sized heat pump system (unlike a gas furnace) doesn’t deliver a ton of excess heat, so it can’t catch up quickly when asked to return to a higher temperature. To compensate, the system might dip into aux heat, and that’s super expensive.

I’m in the US Midwest, where winter temperatures are usually around 15-40 F. I drop from 68 to 60 overnight, and the house can generally coast all night without having to run any HVAC at all. In theory the ecobee should be able to figure out the time required to come back to 68 and start the heat pump early in the morning, but in practice I found it would wait too long, and then the large difference between actual and set temp would trigger aux heat. To avoid this, I added a custom activity in Ecobee’s web interface (I call mine “preheat”), with a temperature of 64. I have my schedule set up with an hour of preheat in the morning, before going to the normal 68. This means there’s less of a delta-T, and the system can heat up entirely using the heat pump.

Ecobee has an API so in theory you can write your own controller. But the last time I tried some random python lib (pyecobee I think?) the auth part was kinda overcomplicated, you need to register an app, enter pin code on the thermostat to authorize it, stuff like that. Still, could be an option.